Project Description

Principle of operation

Jefa brake steering systems can be installed starting from series 100, 150, 200, 300, 400 and 700, 710, 800, 850 columns, or from steering shafts mounted in bulkheads.

The input shaft is 25 mm in diameter on all the columns and has an international 1-inch conical coupling, which allows the mounting of all Jefa wheels up to 1500 mm in diameter.

The wheel axle rests on three ball bearings, two on the front of the column and one on the rear.

All the columns can be equipped with different sprockets in order to obtain the desired reduction ratio. (number of turns of the wheel to bring the rudder from starboard to left).

The columns can be fitted with conventional systems with crossed pulleys, or open cable systems with parallel pulleys. These pulleys are mounted on a wide base that allows a strong fixing.

In addition, it is also possible to install sheathed cable systems, by mounting the appropriate terminal under the column.

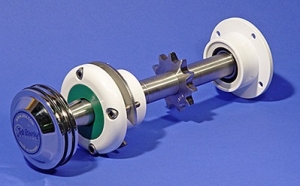

Bulkhead steering shafts

Jefa type BS25 steering shafts have sealed, pre-lubricated ball bearings that are maintenance-free. Jefa’s unique PUR rubber gasket contains no metal parts and ensures maximum durability.

The 25mm diameter stainless steel wheel axle provides a rigid and durable assembly for wheels up to 1300mm diameter.

To determine the number of revolutions of the wheel, see the appropriate table according to the pinion and spoke of the sector.

The internal disc brake allows a progressive and effective locking of the wheel.

For the assembly of wheels up to 1500 mm in diameter, it is recommended to use the special bearing to be installed at the opposite end of the shaft.

Bulkhead steering shafts BS20

Jefa type BS20 steering shafts contain a high efficiency 25mm ball bearing, they are watertight and pre-lubricated and require no maintenance.

Due to the individual bearing arrangement (for compact dimensions) the BS20 shaft should always be used in conjunction with the BS20-sup bearing.

Jefa’s unique PUR rubber gasket contains no metal parts and ensures maximum durability.

The 25mm diameter stainless steel wheel axle provides a rigid and durable assembly for wheels up to 1500mm diameter.

For larger diameter wheels, type BS30 must be used. The internal disc brake allows a progressive and effective locking of the wheel.

Horizontal steering shaft HS25

Jefa HS25 type horizontal steering shafts contain a high efficiency 25mm ball bearing, they are watertight and pre-lubricated and require no maintenance. The stainless steel shaft rotates from

5mm in diameter, it guarantees a rigid and resistant assembly for wheels up to 1500mm in diameter.

An additional pinion for a second rudder or autopilot actuator can be welded to the shaft, please specify the number of teeth and the distance L2. The internal disc brake allows a progressive and effective locking of the wheel.

Bulkhead steering shafts BS30

Jefa type BS30 steering shafts have robust, watertight, pre-lubricated 30mm ball bearings that are maintenance-free. Jefa’s unique PUR rubber gasket contains no metal parts and ensures maximum durability.

The 30mm diameter stainless steel wheel axle provides a rigid and durable assembly for wheels up to 1900mm diameter.

To determine the number of turns of the wheel see the table according to the pinion and spoke of the sector.

The internal disc brake allows a progressive and effective locking of the wheel.

The wheel axle can be supplied in various lengths according to the assembly requirements.

The attachment cone is 25mm, but can be requested in 30mm for Jefa wheels with a diameter of more than 1500mm.

Chain and cable kit

The stainless steel chains with 5/8″ pitch used by Jefa are produced according to the American standards ANSI B29.1 (ISO 606A) which provide a minimum breaking load of 1880 kg.

On the contrary, most other manufacturers of steering systems use chains according to DIN8187 (ISO 606B), which provides a minimum breaking load of 1450 kg.

The chain is non-magnetic like its accessories. The 7×19 stainless steel cables are already spliced with a splice, and a stainless steel roller is provided to distribute the load on the junction link.

The cable is connected to the sector by means of an eye bolt complete with a jig and relative clamps.

Pulleys

Jefa pulley bases are made of extruded aluminium, which gives them greater strength than conventional aluminium castings.

The fixing holes of the base with two pulleys, correspond exactly to the fixing screws of the column, allowing a simple and quick assembly.

The swivel pulleys have a base with 4 fixing holes for M8 screws. The oval shape of the holes allows an accurate orientation of the base, in order to allow a perfect alignment of the pulley groove with the cable.

The base of the fixed flat pulley is fixed with 4 M10 screws.

All pulleys are CE approved, which means that they have a higher breaking load than the corresponding cable used.

Conduit tube, accessories and terminal units Tangential

The Jefa conduit terminals are made of solid bronze and the inner part has a large pitch thread that allows you to easily screw it onto the conduit tube.

Thanks to the 16mm external thread with nut and lock nut, the terminals can be fixed securely on a bulkhead or on the appropriate terminal units.

The 16mm high strength sheath tube is reinforced with steel wires and a Teflon tube inside ensures very low friction and long life.

Jefa tangential terminal units are suitable for boats from 30 to 45 feet and for sectors with a minimum radius of 300.

These terminals are used when the position of the sector on certain boats does not allow a normal route for the cables.

These terminals are used when the position of the sector on certain boats does not allow a normal route for the cables.

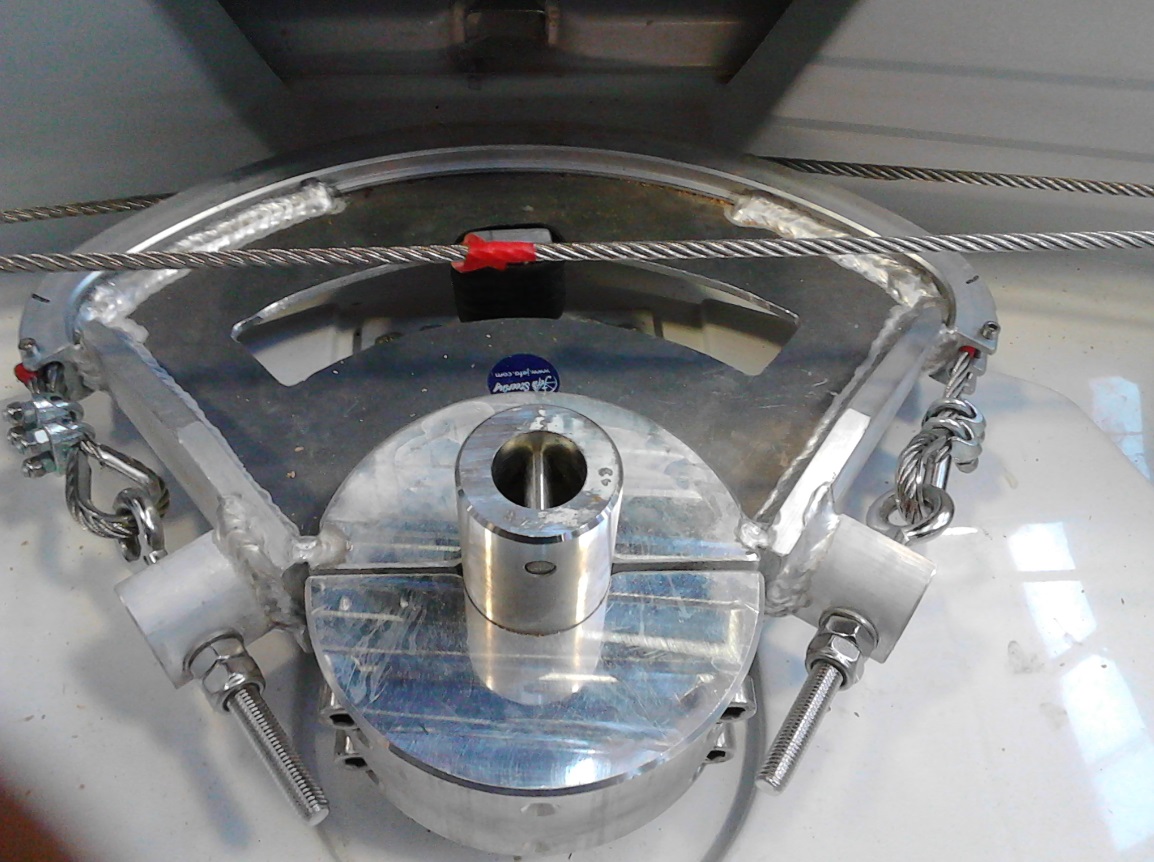

Quadrants

All Jefa sectors are made of high strength aluminium EN6082 (AlMgSi1) which has excellent resistance to stress and impact.

The realization with parts from solid and welded gives the whole a strength much higher than the similar realizations obtained by fusion.

The presence of the double groove facilitates the assembly allowing to cross the cables between the pulleys and the sector.

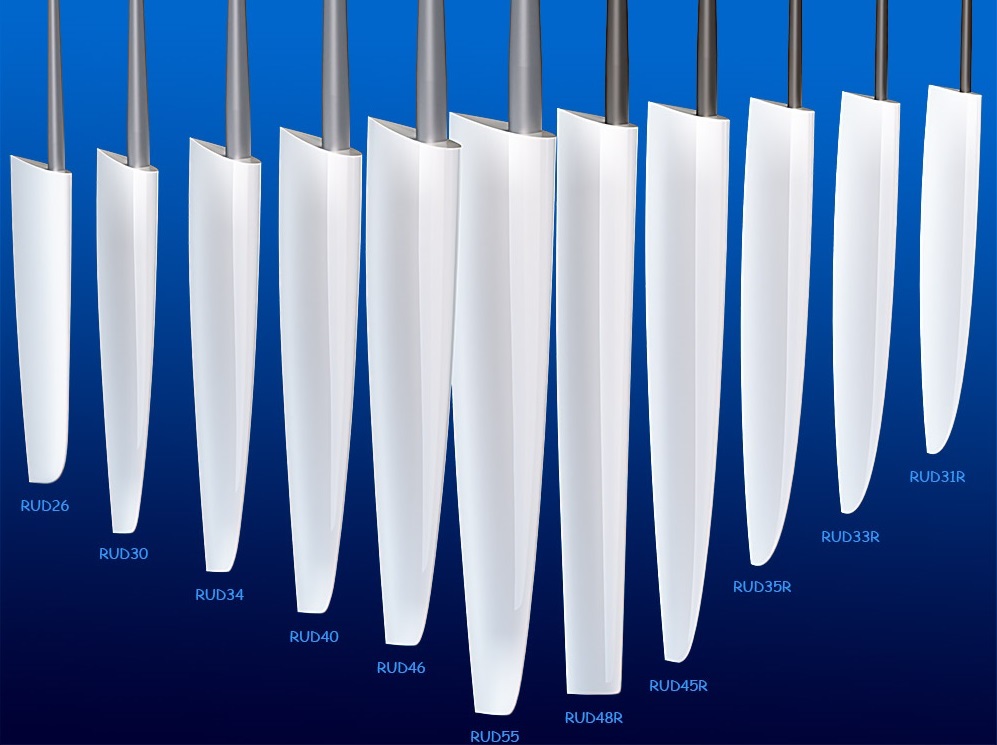

- COMPLETE RUDDER BLADES WITH SHAFTmarioberlati2021-03-26T08:24:31+01:00

COMPLETE RUDDER BLADES WITH SHAFT